Over the past few years, Komatsu has recorded a significant reduction in lost-time accident rates throughout the region. These results reflect the joint effort and combined commitment to safety and health of the company and its distributors.

As a result of implementing a robust preventive model, accompanied by advanced tools, such as: Preventive Hand, Cardinal Rules, Responsible Refusal to Substandard Work (NRTS) and effective practices within the framework of the Joint Working Model (JWM), which have been developed and perfected over the last few years, we have reduced the exposure of employees to risk conditions, improving the safety culture in infrastructures and operations where Komatsu is present.

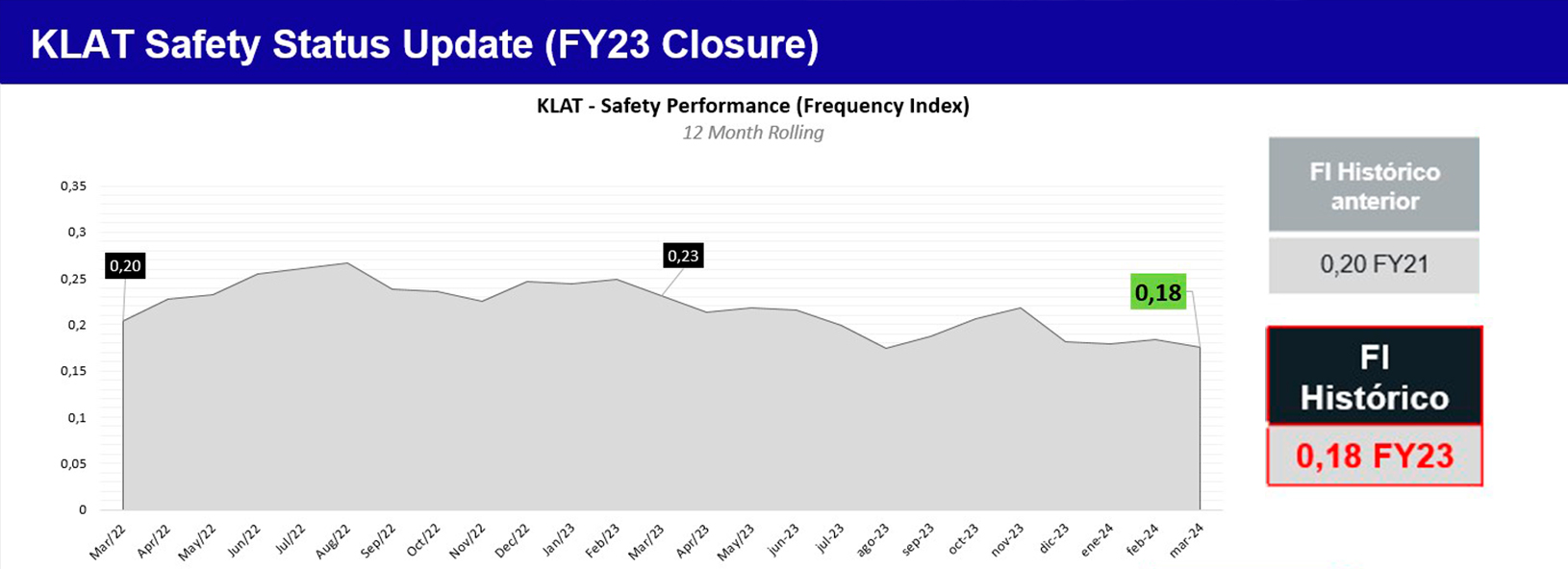

The frequency indexes for the last fiscal years have been:

2021: 0,23

2022: 0,23

2023: Outstanding 0,18

“This decrease in occupational accidents confirms that our preventive model is working thanks to the correct implementation of our distributor network. We will continue to work together to face the challenges of the future”.

Andrés Cañas

Assistant Manager of Safety and Health Strategy

Komatsu Latin America’s distributor network

“Thanks to the SSOMA program and the support of the team, we have made progress day by day, giving us many tools so that our collaborators can carry out their work with high safety standards and at the same time be committed to caring for the environment, thus achieving the incredible benefit of zero occupational accidents in the company as an integral part of our work culture”.

Rafael Bernal

Regional Machinery Manager of official distributor

Komatsu Grupo Construmarket Guatemala

The effectiveness of preventive strategies is largely due to the commitment and active cooperation of distributors. Collective effort is essential to achieve positive results, demonstrating that, with dedication and teamwork, we can create safer and healthier work environments.

We have several success stories, but we would like to highlight the following on this occasion:

Komatsu Colombia: Reduction of frequency rate from FY2021 to FY23 by 71%.

Grupo ConstruMarket Guatemala:Significant improvement in the infrastructure of its facilities and safety culture of its employees.

Genequip: Obtained certification in the “Heath, Safety, Security and Environment Management System mentorship program” with the Center for Local Business Development.

“These results give us lots of hope and confirm that we are on the right track. We will continue to work tirelessly to improve our safety practices, although we must not be complacent; we must continue to improve our processes and reinforce preventive actions”.

Erick Kaempfer

Regional safety and health manager

Komatsu Latin America

For more information, please contact: andres.canas@global.komatsu